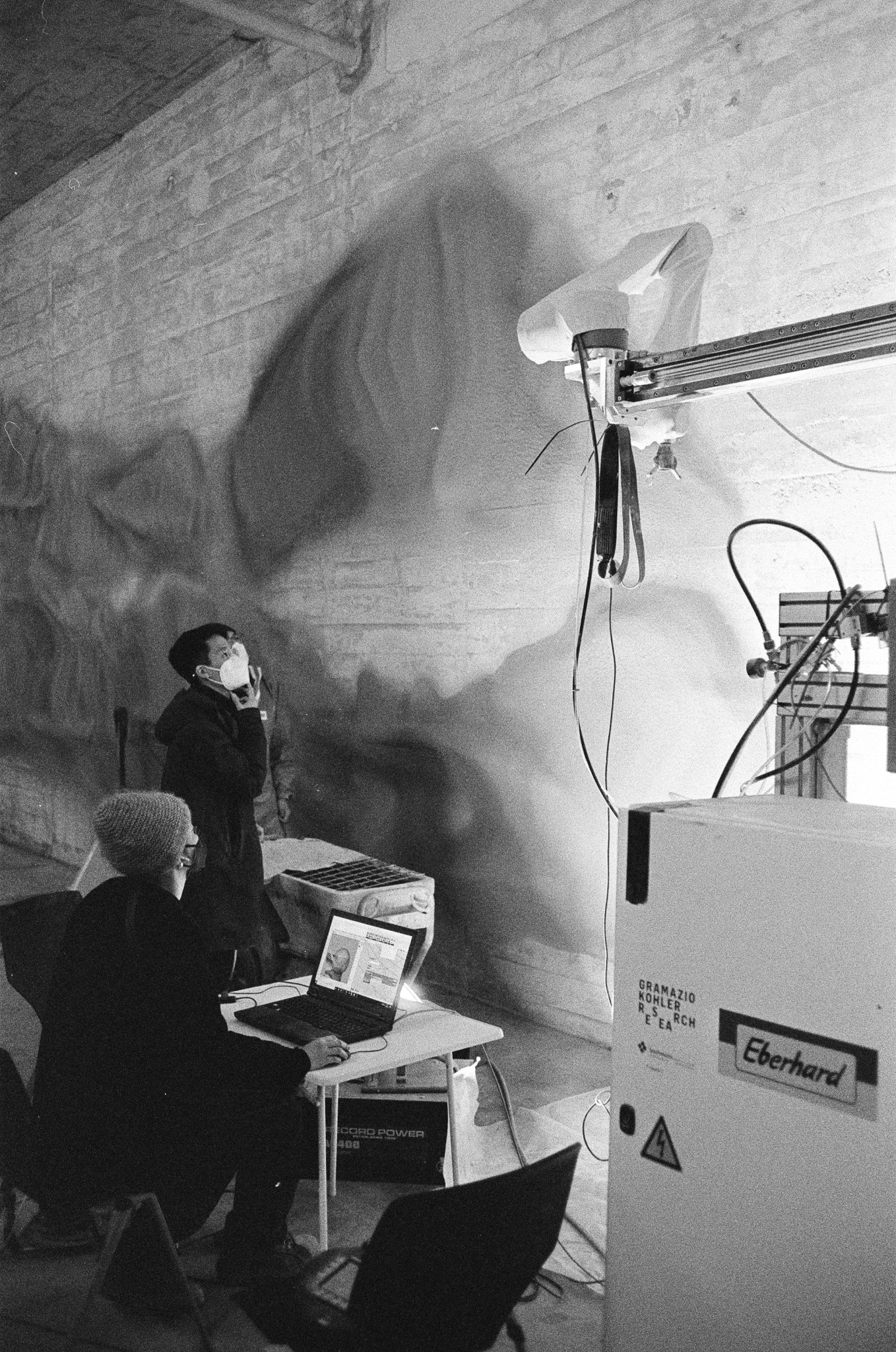

Human-machine collaboration for robotic fabrication

Year : 2021

Place : Rümlang, Zürich, Switzerland

Role : Developed adaptive, non-planar spraying trajectories for robotic 3D spraying using a UR10 robot, integrating parametric toolpath planning and custom algorithm development.

The Project in Numbers:

Size : L 16.8m, W 5.8m, H 5m

Material : Plaster

Software : Rhino, Python, Grasshopper

Setup : 1x UR10 Robotic Arm with Siemens Axis, HTC Vive Tracking System, Hilti Total Station

Instructors : Daniela Mitterberger, Selen Ercan Jenny, Eliott Sounigo, Ping-Hsun Tsai, Petrus Aejmelaeus-Lindström, David Jenny, Hannes Mayer

Intuitive Design Team : Carlos Wilkening, Foteini Salveridou, Lena Kitani, Priyank Soni

Design Team : Artemis Maneka, Guillaume Jami, Pascal Bach, Simon Griffioen

Fabrication Team : Beril Önalan, Chan Yen-Fen, Co Tsuruta, Evgenia Angelaki, Ilaria Giacomini, Liya Sunny Anthraper, Wei-Ting Chen, Wei Chengyuan

Supporting Technicians : Philippe Fleischmann, Michael Lyrenmann, Andi Reüsseer, Tobias Hartmann

Industry Partners : Eberhard, Giovanni Russo AG

Intuitive Robotic Plastering, a 11-week T2 project of the MAS ETH in Architecture and Digital Fabrication explores the potential of novel digital fabrication processes to implement a full-scale construction project at Rümlang, Zürich. The topic combines 2 Gramazio Kohler Research’s ongoing projects, Robotic Plaster Spraying and Human-Machine Collaboration, to propose new design and fabrication methodologies under the name of Intuitive Robotic Plastering. On one hand the concept of Human-Machine Collaboration(Intuitive Design) is too think how human gestures are used as a design tool expressing very singular and sensible design process. On the other hand, Robotic Plaster Spraying allows to think through a different paradigm where and how plaster is applied by iteration of fine and subtle layers on the wall.

Intuitive Design

The intuitive design workflow begins with the input of the human gesture. The users have an immediate visual feedback on their work which allows they to adjust the input accordingly. The gesture is tracked by HTC Vive system and the recorded data gets adjusted to the fabrication parameters by the interactive system developed in Rhino Grasshopper.

Prototyping

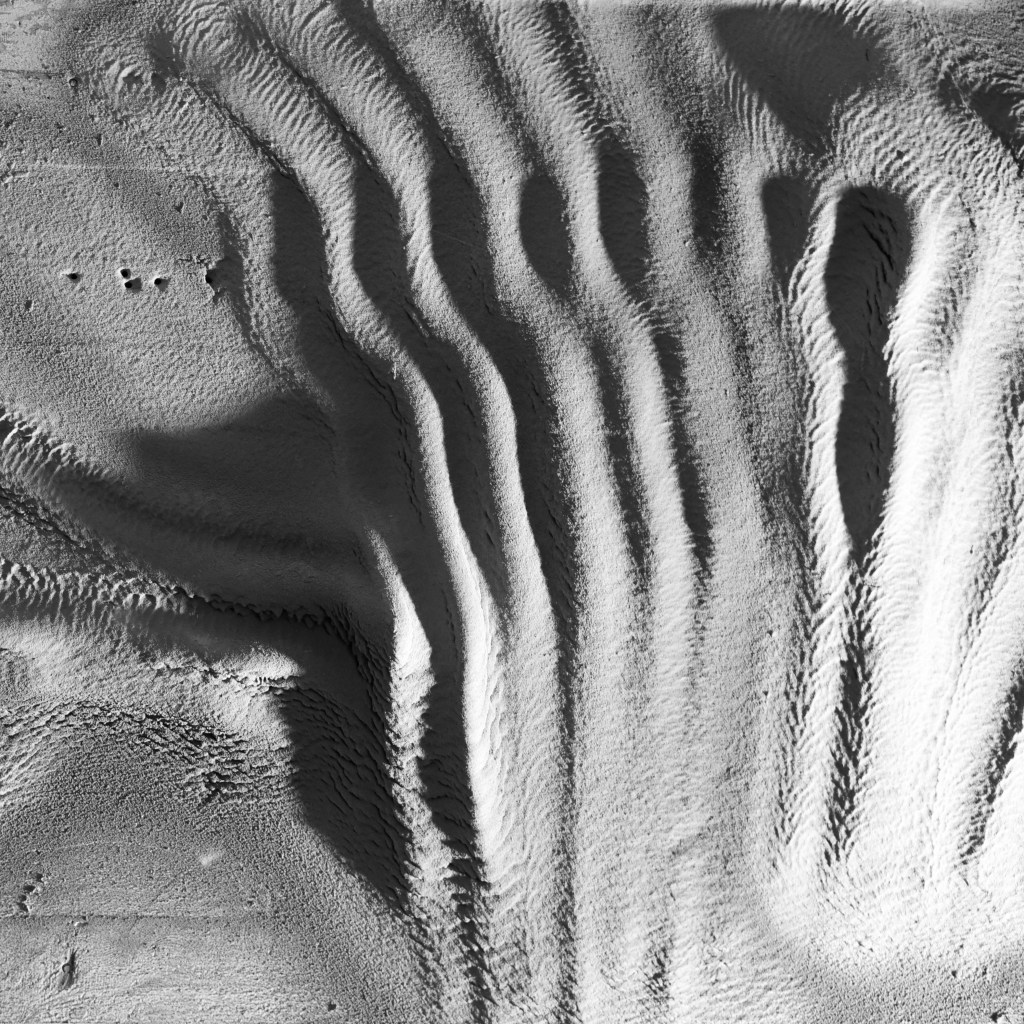

Before moving to the site, Rümlang, a series of prototyping is conducted by spraying plaster on the 1.2m x 2m panels, which largely helps us understand the influence of parameters like velocity, angle and distance of spraying(end-effector distance) on the material behavior.

Spraying Method

The three basic parameters are took into account to develop the on-site robotic spraying strategy. As the robot moves closer to the wall, the velocity becomes higher and this is where the “carving effect” of the material becomes visible. In addition, we applied a Pitch end-effector angle(along the Z axis) on the ends of the spraying paths to achieve material fading out and a Yaw angle(along the Y axis) to play with texture. Last, the end-effector distance and velocity of spraying are extracted from recorded human gesture, and the values are remapped based on the limitations of the robotic arm setup.

Scan

Depending on the growth of material, we scan the sprayed result every 10-15 layers. The scan process is introduced in order to maintain the end-effector distance. Therefore the robot always follows the input distance values while building volume. In addition, we are interested in how to further utilize the scan process for optimizing the result. To that end the second dynamic pitch angle is applied to every individual target point, by collecting the normal vector from to the neighbor scanned mesh faces around it. Consequently the material is more evenly distributed and material failure is significantly avoided.

Moving On Site

Global localization and local segmentation are two important parts of on-site fabrication. For the global localization it requires 11 tower positions to finish the overall design and the local segmenting , base on the robot reachability and the design, it requires 2 to 4 axis positions to cover the design of current tower location.

The final result is the design and construction of an interior space within an existing structure at Rümlang. The room offers us approximate 200m² to apply an adaptive thin layer printing process with an interactive design procedure – where a robotic arm sprays plaster following recorded hand gestures, creating an interplay between human instructed and digitally controlled fabrication processes with new aesthetic of conventional material.