3D-Printed Facade

Year : 2020

Place : ETH Zürich, Switzerland

Role : Developed custom Python scripts for non-planar robotic printing; prototyped toolpaths with a UR5 arm.

Material : PETG, TPU

Software : Rhino, Python, Grasshopper

Setup : 1x UR5 Robotic Arm

Team : Chan Yen-Fen, Lena Kitani

Instructors : Petrus Aejmelaeus-Lindström, Ina Cheibas, Matthias Leschok, Remy Clemente, Valeria Piccioni, Ioanna Mitropoulou

3D Printed Facade, a 5-week project of the MAS ETH in Architecture and Digital Fabrication focuses on 3D robotic printing facades. The students learn and develop fabrication-aware design strategies for additively manufactured facades. The 16 students are divided into 8 groups, develop computational design methods, and fabricate 1:1 prototypes, using a custom robotic polymer extrusion setup.

Topics like structural integrity or active shading are chosen depending on each group’s interest. Our work Hop n Weave explores alongside aspects of permeability and rigidity. Through an iterative process of designing and 3D printing the aim is to develop smart, innovative, and integrated facade components.

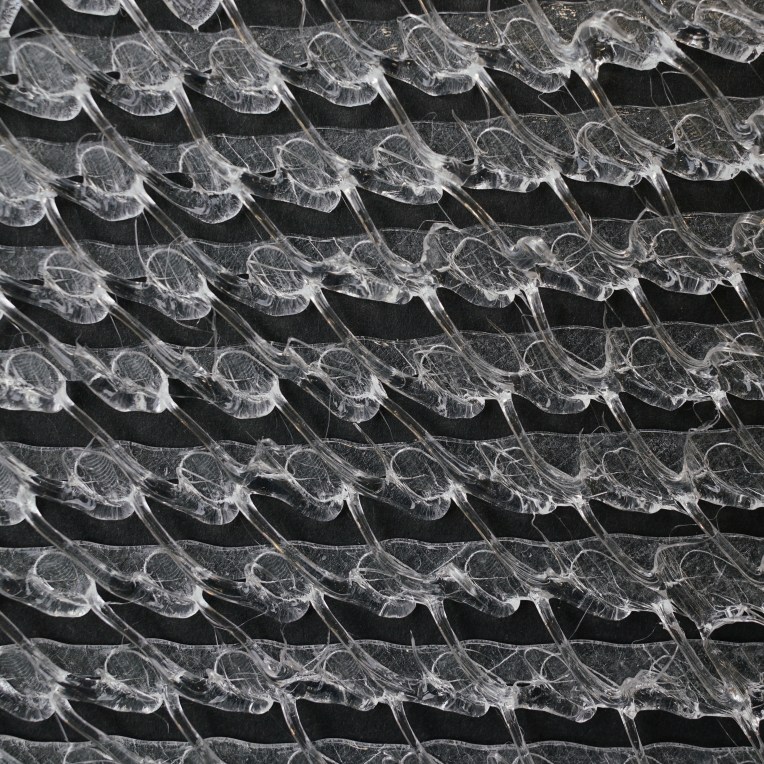

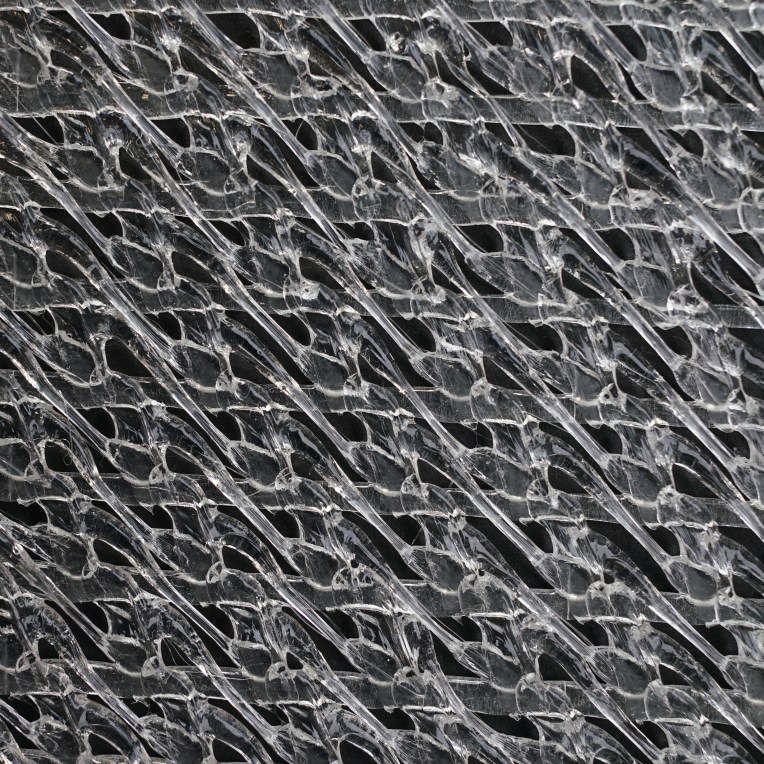

Initially we tested with the rigid material, PETG, with programmed robot movement that continuously changes the height and velocity. This method not only introduces breathability and flexibility but aesthetic patterns to the outcomes. Through the experiment the key parameters are found and recorder for optimizing the quality.

PETG_Tryout 1

Single Layer, Pattern Offset

Temperature : 230

Layer Thickness : 1.3mm

Z Hop : 15mm

Base Velocity : 15/1000 m/s

Hop Velocity : *2.5, *1.5, *3, *3, *1.5

Flat Velocity : *2.5

PETG_Tryout 3

Single Layer, Pattern Offset

Temperature: 230

Layer Thickness: 1.3mm

Z Hop : 3mm

Base Velocity : 12/1000 m/s

Hop Velocity : *1.5, *1.5, *3, *3, *1.5

Flat Velocity : *3

PETG_Tryout 2

Single Layer, Pattern Offset

Temperature : 230

Layer Thickness : 1.3mm

Z Hop : 5mm

Base Velocity : 15/1000 m/s

Hop Velocity : *2.5, *1.5, *3, *3, *1.5

Flat Velocity : *3

PETG_Tryout 4

Double Layer, Pattern Offset

Temperature : 230

Layer Thickness : 1.3mm

Z Hop : 5mm

Base Velocity : 15/1000 m/s

Hop Velocity : *2.5, *1.5, *3, *3, *1.5

Flat Velocity : *3

Second, the material is switched to TPU to provide more flexibility for the printing. As can be seen from the photos, the printing quality significantly decreases as the model grows higher because TPU is softer than PETG, which is the reason why we switched to print horizontally on the flat printing bed afterwards.

TPU_Tryout 1

Single Layer

Temperature : 230

Layer Thickness : 1.3mm

Z Hop : 15mm

Base Velocity : 15/1000 m/s

Hop Velocity : *2, *3, *3, *,2.5 *2.5

Flat Velocity : *1

TPU_Tryout 2

Single Layer

Temperature : 230

Layer thickness : 1.3mm

Z hop : 15mm

Base Velocity : 15/1000 m/s

Hop Velocity : *2, *3, *3, *,2.5 *2.5

Flat Velocity : *0.8

TPU_Tryout 3

Single Layer

Temperature : 230

Layer Thickness : 1.3mm

Z Hop : 10mm

Base Velocity : 15/1000 m/s

Hop Velocity : *2, *3, *3, *,2.5 *2.5

Flat Velocity : *2.5

TPU_Tryout 4

Single Layer, Pattern Offset

Temperature : 230

Layer Thickness : 1.3mm

Z Hop : 15mm

Base Velocity : 15/1000 m/s

Hop Velocity : *1.5, *3, *3, *,2.5 *2.5

Flat Velocity : *1.8

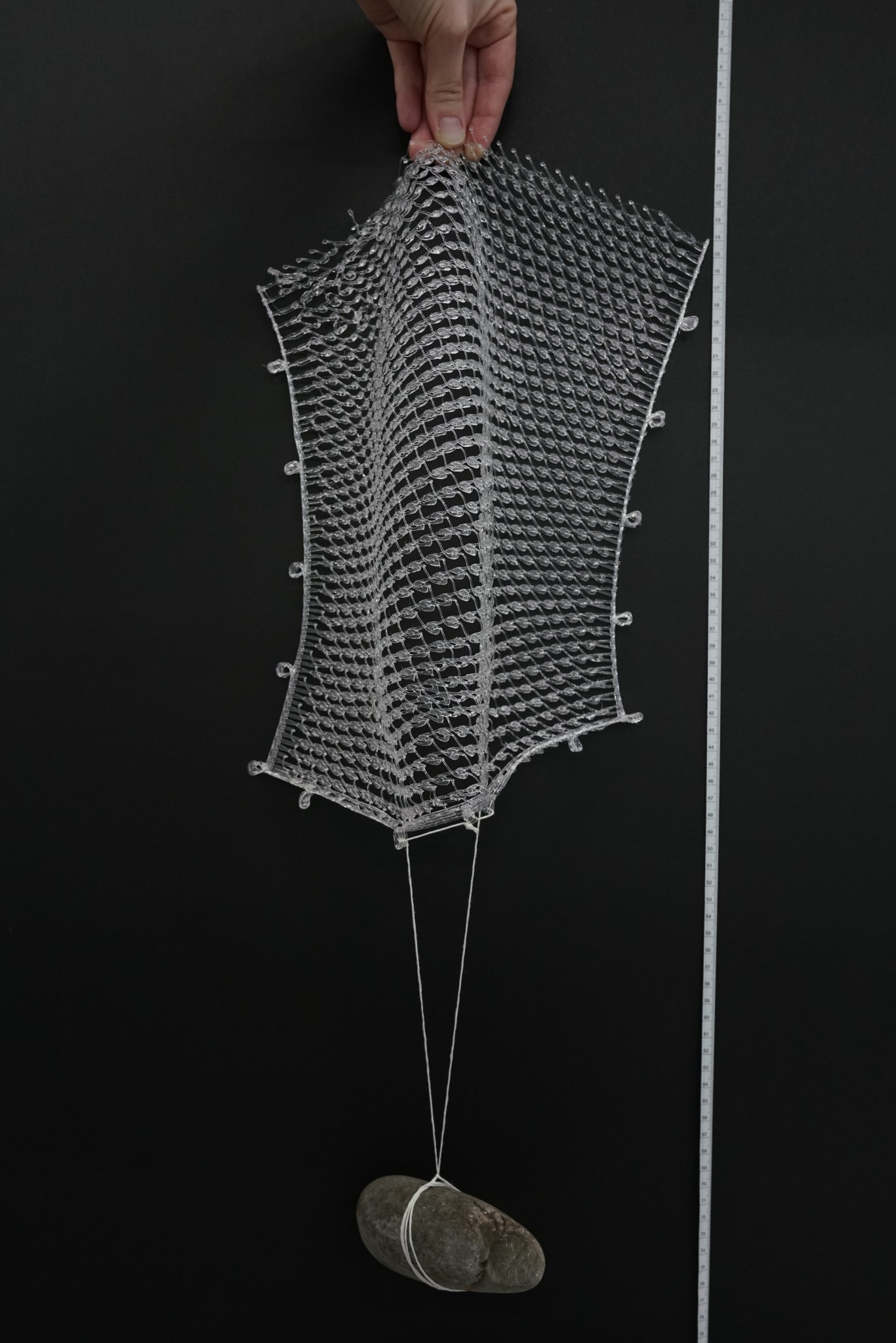

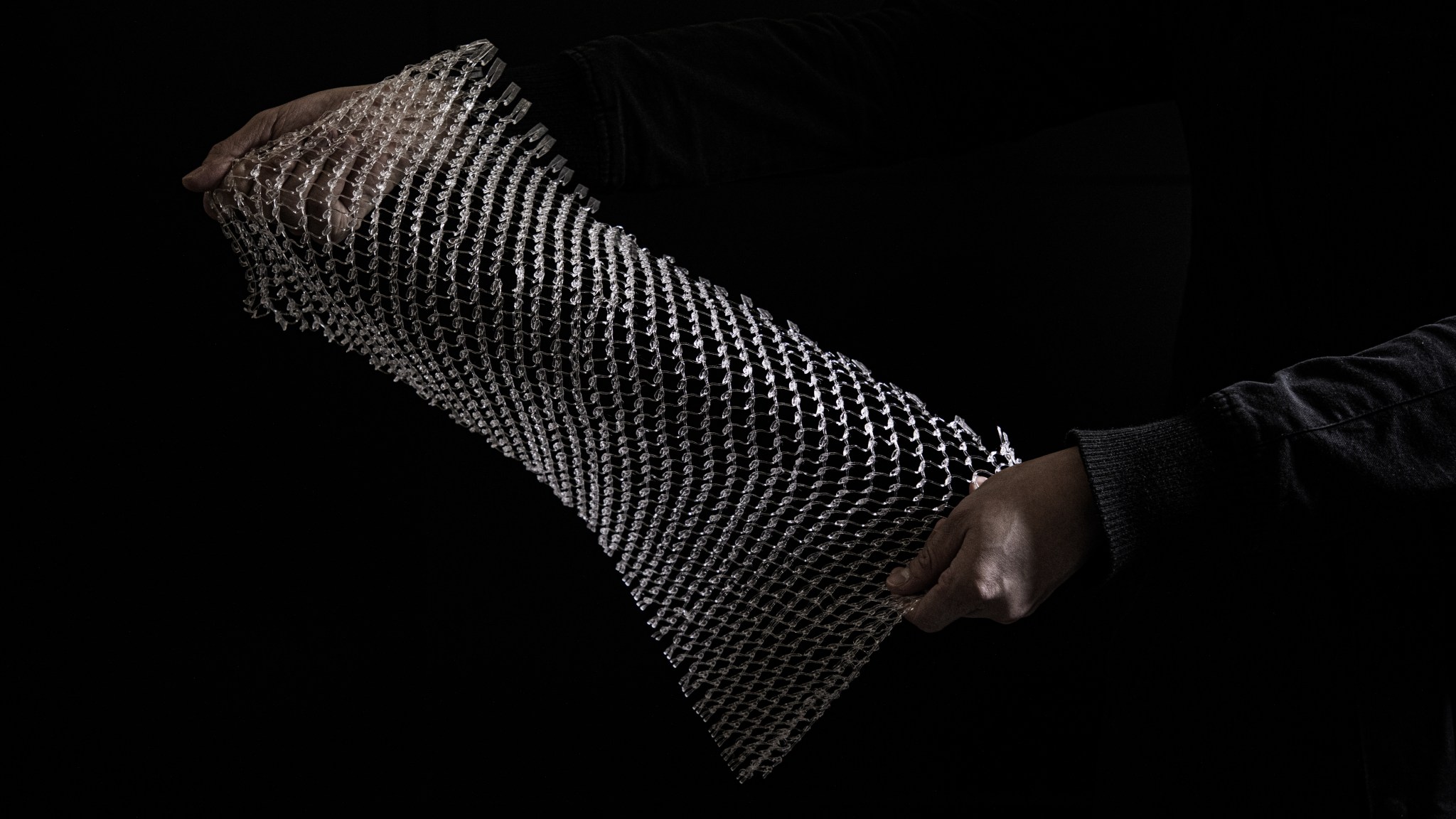

To refine the outcome of the horizontal TPU printing, the parameters like nozzle height, velocity and print environment have to be adjusted precisely. The final TPU skin with highly aesthetic pattern has proved to be sufficiently flexible.

To have the maximum extension of the TPU print, the joints connecting every pattern unit need to be released in advance. The TPU print can be stretched with force applied to the one diagonal and the one vertical to the direction of the weave.